AI and IoT: Unleashing the Power of Digital Twins - Part I

AI and IoT: Unleashing the Power of Digital Twins - Part I

Digital twins have the potential to revolutionize product life-cycle management and generally how we build, design and operate complex systems.

Demystifying Digital Twins

So what exactly is a digital twin? Let's take a trip back in time to April 13, 1970, when the crew of Apollo 13 reported a critical condition. "Houston, we've had a problem here," they said. The ground crew quickly replicated the state and inventory of the spacecraft and set to work devising solutions to fix pressing issues like air filtration. What they were using was a physical twin of the spacecraft – a mock-up that allowed them to find a solution faster. Now, imagine the same situation today, but with the entire spacecraft and flight plan modeled in a virtual environment – that's a digital twin.

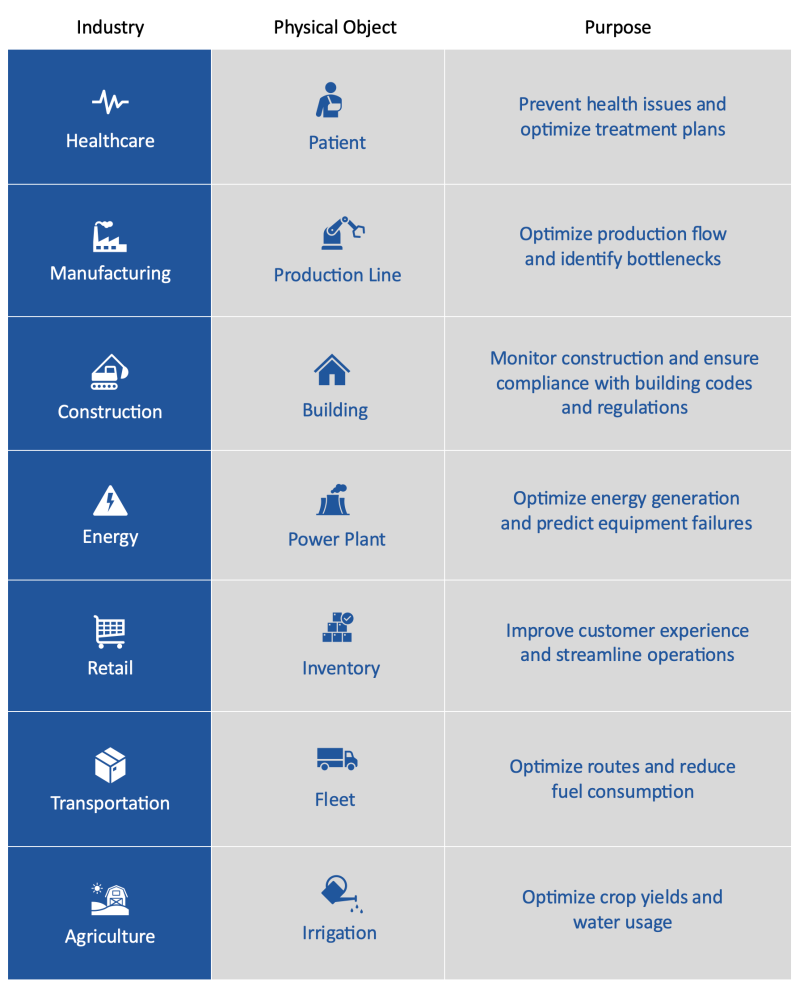

A digital twin is a virtual representation of a physical object or process. There is a tendency to associate the concept of digital twins with jet engines or wind turbines, which represent typical use cases. While energy, aviation, automotive are all great and very common areas where digital twins are applied, they do not provide a complete picture. Both the concept of digital twins and its applicability are frequently misunderstood. Digital twins go far beyond wind turbines and jet engines, they are applicable to any industry that deals with physical products, systems or processes.

How Digital Twins Work

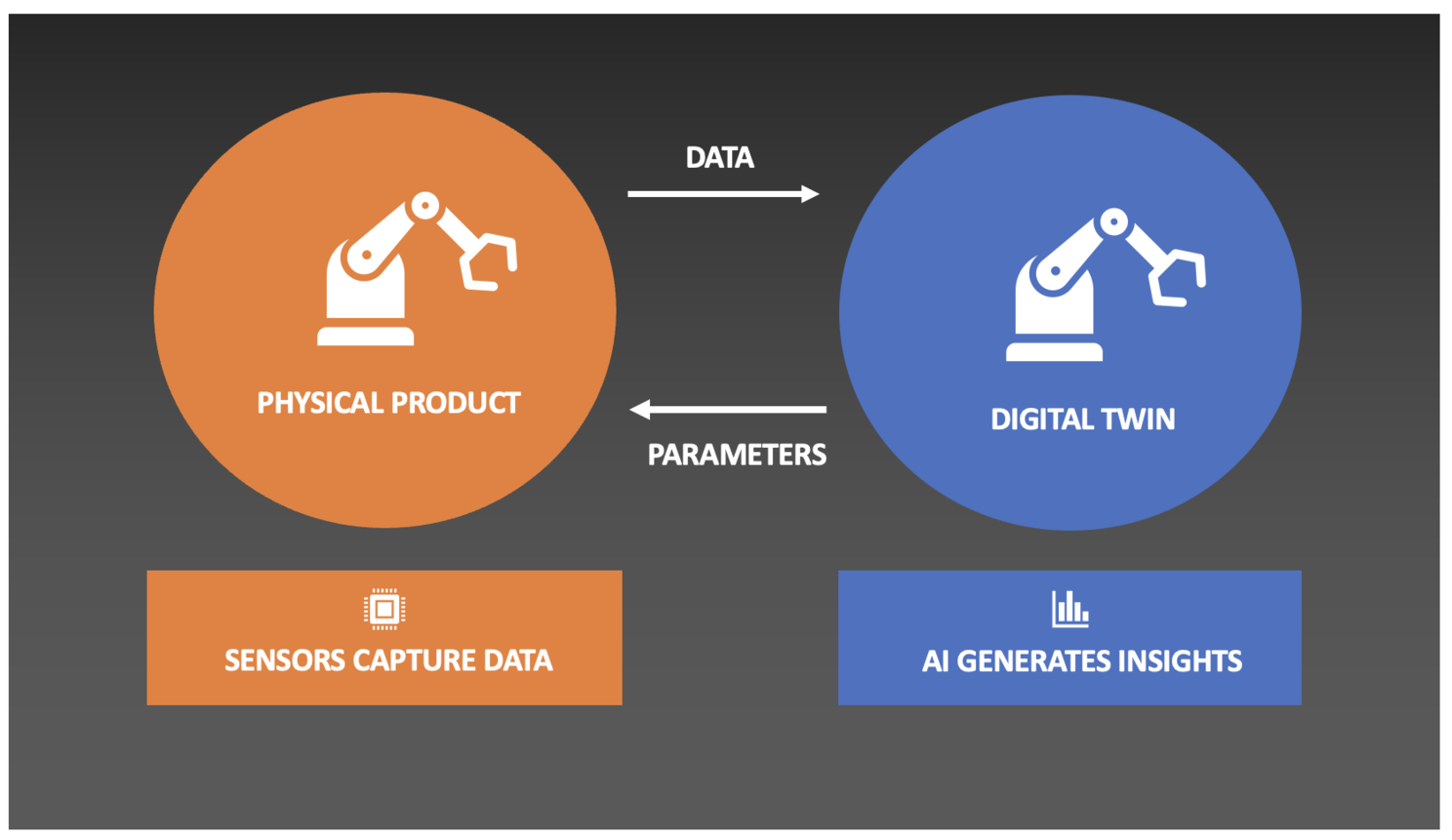

The emergence and increasing adoption of digital twins has been fueled by recent advancements in IoT and AI technologies. A digital twin is not just an isolated digital representation of a physical object. One of its key properties is connectedness. This means the ability for data to flow from the physical world to the digital and back. IoT is enabling because sensors can be used to capture real-time data about the physical world and feed it to the digital twin. AI is enabling because it can be used to both drive insights and model real world processes in the digital word. The insights gained can then be communicated back to the physical object to inform improved operation.

Digital twins come in several types, depending on the level of integration between the physical and digital twin. There's the digital model or prototype, used when the physical side isn't ready, the digital shadow, which follows the physical state automatically, the digital twin instance, which represents a unique copy of a real product, and the digital twin aggregate, which represents a class of product.

Most importantly a digital twin can represent any system or process that generates data. The data does not have to come from sensors. One example which may not be a typical is an e-commerce website. The data there is generated by customer interactions and not sensors. There is very much a need to experiment with various recommendation and personalisation algorithms before they are deployed in the real system. AI can be used to model and simulate customer responses which are complex in nature.

It is also possible to implement digital twins that do not involve any AI, where processes are modeled using the laws of physics and mathematics. However, most systems are too complex to explicitly model all the governing laws. AI allows us to learn the governing laws from data and forecast what may happen in the future.

Key Business Benefits of Digital Twins

Digital twins can have a significant impact, among other things the business benefits include:

-

Improved operational efficiency: Digital twins can provide real-time data on how assets, systems, and processes are performing, allowing companies to optimize operations.

Reduced downtime: Digital twins can help companies model anomalies and identify problems before they cause a downtime.

Increased product quality: Real-time data on how products are being produced, can be used to identify and fix quality issues before the product is shipped to the customer.

Improved safety: The collected data can be analyzed to assess and address safety hazards before they cause accidents.

Reduced costs: Usage data can help companies address problems that are wasting resources and driving up costs.

Improved customer satisfaction: Digital twins can help companies ensure that products are of high quality and meet customer expectations. This can lead to increased customer satisfaction and loyalty.

Increased competitiveness: By optimizing operations, reducing downtime, and increasing production, digital twins can help companies become more competitive in their industries.

Digital Twin Use Cases

The following use cases across industries illustrate how digital twins are used:

How AI Is Enabling Digital Twins

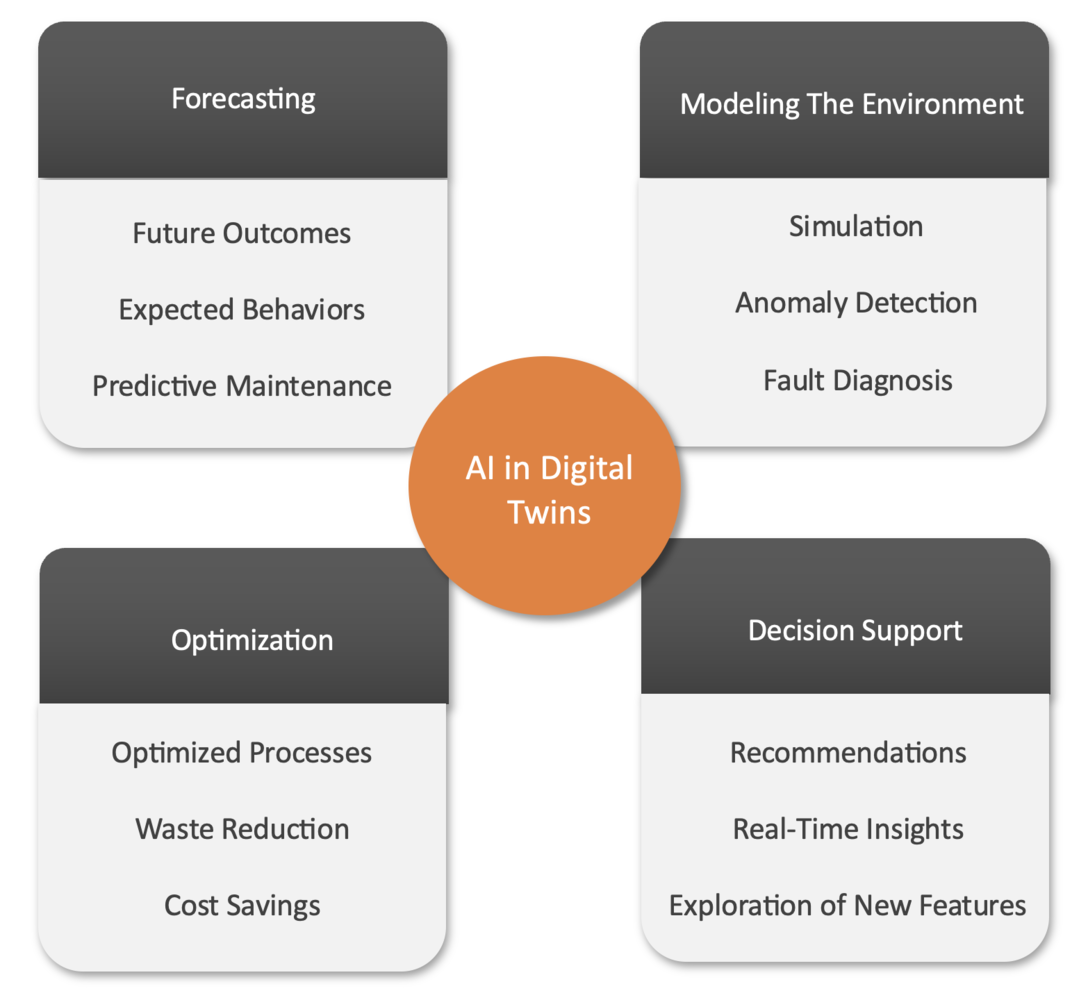

A digital twin ingests real-time data. Provided that the quality of the data is good, it presents a great opportunity for AI to drive value. Depending on the use case there is a wide variety of ways in which AI can be used. Broadly we can think of four categories of applications.

A physical object typically interacts with its environment. A car might be driven across the United States. A patient might live a very unhealthy life style. AI can be used to model the environment, interactions with the environment or the state of the twin itself. This is useful because we can then reason about how changes to the the physical object might affect its use. Furthermore this type of modeling allows us to assess uncommon behavior and identify faults.

Another way in which AI can add value is in forecasting future outcomes, behaviors and events. Past data can be used to predict what might happen in the future. Specific applications that come to mind here are forecasting of usage or predictive maintenance.

More To Follow...

The second part of this article series is coming soon. It will cover pitfalls when implementing digital twins, available vendors and tools.

Interested To Learn More?

As a team of innovators passionate about delivering smart technology solutions, we can guide your company on our journey towards implementing and leveraging digital twins. Feel free to reach out at info@reliancy.com.