How Process Mining Maximizes Your Competitive Edge

How Process Mining Maximizes Your Competitive Edge

You have set your company on the path of digital transformation. Most aspects of your business are integrated, recorded and monitored. Your leadership is on board and committed. Your workforce is encouraged and motivated. Everybody is on board to reduce and remove that work that is mind numbing or back breaking. All is ready for the next step, robotic process automation or RPA, so now what?

The Missing Piece of Your Automation Puzzle

Hold your horses that's what!

McKinsey reports that 70% of resources allocated to automation are spent on pre-flight activities [1]. Pre-flight activities include identifying, prioritizing and understanding which tasks should be automated. To top it all off, a study by Deloitte shows only about 3% of the automation projects implemented are able to scale [2].

One of the first and most critical obstacles in realizing full benefits of RPA is this: How do we know what to automate? The answer lies in process mining.

Process mining is a technique and a set of tools to analyze and improve business processes. As result of this effort processes can be identified which are well-suited for automation.

Using process mining can significantly reduce costs tied to automation pre-flight activities. It also has the potential to make RPA implementations more effective by helping identify the best processes to automate.

Process Mining: The Bigger Picture

Process mining is a method to analyze observable processes, establish their causality, enumerate their costs and benefits with the goal to ultimately improve existing business processes.

You can think of process mining as providing business intelligence to better understand how current processes function. It helps identify areas that work well, areas that have bottlenecks, areas that are good candidates for optimization or automation.

In other words process mining is not just relevant for automation, but is a valuable tool for analysis and process improvement in a broad sense.

So how does it work?

Several approaches to effective process mining exist. Some are new and made possible by recent advances in computing. Others have been around since Henry Ford and before.

-

Manual introspection by process engineers.

Analysis of manufacturing executing systems (MES) that capture real-time data on manufacturing operations.

Material flow analysis focuses on movement of materials thru the manufacturing process.

Root cause analysis looks at quality and downtime events and it can include maintenance and warranty data.

Event log analysis examines the steps taken during manufacturing and is most generic method since it can incorporate other methods in a well-integrated environment.

Roughly we can categorize the approaches into two buckets, a manual assessment and a variety of data-driven approaches.

The Key Question to Ask

The question is not should we be doing process mining. A systematic approach to process analysis is undeniably valuable. The key question manufacturers should be asking is this: Are we collecting the right data to facilitate effective process mining?

Process Mining: The State of the Art

There are established and sophisticated software tools for process mining. Frameworks for robotic process automation also frequently include components that help with process mining.

Most of the available software tools rely on event logs and event log analysis plays an essential role. For manufacturers who are interested in using common process mining tools it is therefore crucial that process event logs are captured.

Typical capabilities provided by process mining tools include:

- Process Discovery: Event logs are traced, and execution graphs/diagrams established based on evidence in an automatic fashion. Such graphs must be reviewed, and proper context attached.

- Conformance Checking: Automated evaluation of discovered process models to assess quality and discrepancies.

- Process Enhancements: A contextualized execution graph carries expected inputs/outputs, time and cost and meaning of each step. Such graphs can be fed to sophisticated planning algorithms to find better alternatives.

- Process Predictions and Simulation: AI approaches can be used to predict the next activity in a process or estimate the time to completion. AI models or what-if simulations are used to evaluate different process scenarios and their impact on performance.

Process mining is an evolving field and it encompasses a variety of sub-areas such as process modeling, statistical analysis, AI, machine learning and data mining.

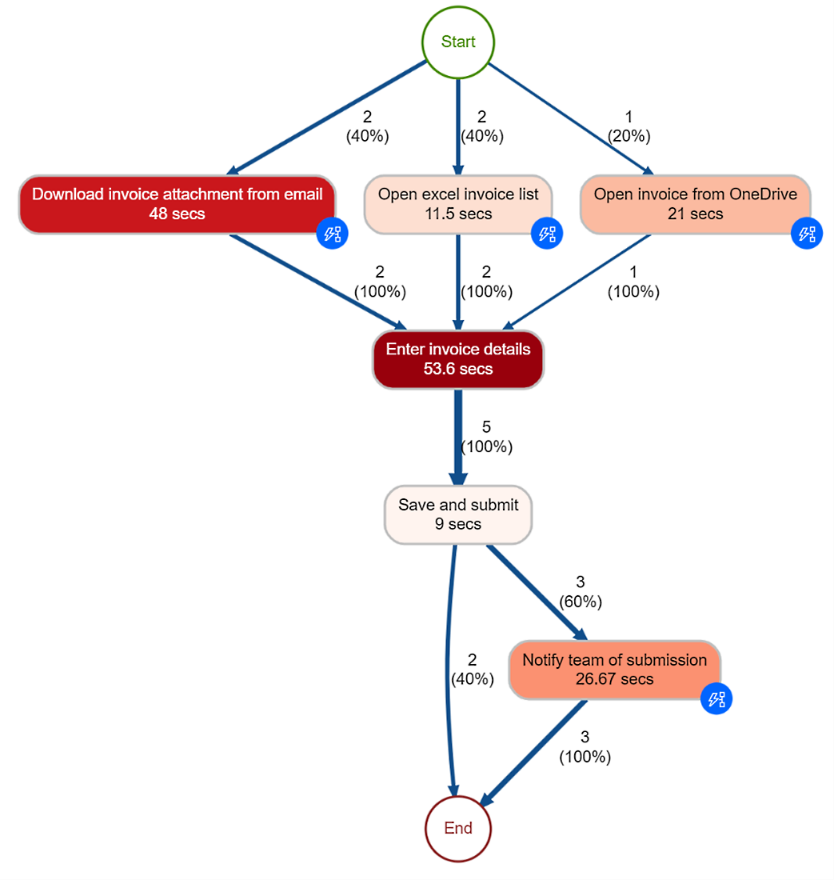

The following graph is called a process map. It is only one of many ways to represent a process. It's an example to help visualize what the output of a process mining effort could look like.

The Benefits

Since process mining serves as a first step for a variety of initiatives it's non-trivial to quantify statistics on cost reductions and productivity gains. It's best to consider the value one gets from activities where process mining plays a crucial role such as process optimization, business process management or robotic process automation.

Robotic process automation in particular has played a big role in elevating the importance of process mining. This is in part due to the significant impact of RPA to the bottom line [2]. RPA improves productivity in 86% of cases, provides a cost reduction in 59% of cases and a payback in less than 12 months.

The benefits of process mining as the first and crucial step include:

- Process Visibility: A clear and objective view of how processes are executed

- Continuous improvement: Provides organizations with the data-driven insights necessary to identify areas for improvement, evaluate the impact of changes, and monitor the ongoing performance.

- Improved efficiency and cost savings: Concrete, evidence-based projections are produced to justify decisions. Enables performance analysis and optimization of processes.

- Improved compliance: The systematic nature of process mining tends to be less error prone when it comes to adhering to regulations.

- Enhanced customer experience: Execution is standardized and streamlined, making processes reliable and predictable in performance and time.

- Improved agility: By quickly identifying areas of improvement, process mining leads to better informed decision-making and faster-to-market reactions.

The Role of Artificial Intelligence

In order to extract relevant and actionable information from event logs, sophisticated data analysis approaches are required. Artificial intelligence (AI) therefore plays a key role in process mining. The following is an illustration of ten use cases of AI in process mining:

A number of these approaches tend to be implemented in available process mining tools. Companies that are interested in extracting further value, initiate tailored AI efforts.

The Recap

Process mining can underwhelm for several reasons. Technical pitfalls include lack of data, data quality, complexity of processes and poor integration of underlying systems.

Hopefully this article explains key concepts of process mining and helps you put it in the right light. No treatment would be complete without discussing challenges as well as benefits.

Organizational pitfalls include human experience, organization culture and privacy/security concerns.

At Reliancy we have been involved in process mining for various industries. Given the significant role of AI in process mining, we are uniquely qualified to help our clients navigate the adoption challenges and get the most value out of process mining.

As a solution provider, Reliancy is an official partner of both IBM and Microsoft. Both companies offer trusted and highly ranked capabilities for process mining. We help our clients choose, adopt and implement the most fitting solution.

Sources

- McKinsey, Changing Change Management (https://www.mckinsey.com/featured-insights/leadership/changing-change-management).

- Deloitte - Annual Global RPA Survey Report (https://www2.deloitte.com/ro/en/pages/technology-media-and-telecommunications/articles/deloitte-global-rpa-survey.html).